RockWatch: The Art of Crafting Watches from Stone

Innovation has long shaped Tissot’s approach to watchmaking. Drawing inspiration from nature, the Swiss landscape, and its own heritage, the brand has continually challenged the boundaries of traditional design through material experimentation.

In 1969, the Sidéral introduced fiberglass to watchmaking, lightweight, resilient, and radically modern. This was followed by the Idea 2001 in 1971, the world’s first plastic mechanical watch. These bold steps into unconventional materials naturally led to one of Tissot’s most audacious creations: the RockWatch, launched in 1985 and crafted from granite.

In 2025, the RockWatch returns as a limited edition, reaffirming Tissot’s pioneering spirit. Inspired by the belief that nature itself is a blueprint for progress, each piece is carved from granite sourced from the Jungfrau, making every watch inherently unique. Shaping stone into timekeeping form is a technological feat requiring advanced machining and deep respect for both material and craft. The RockWatch is at the meeting point between nature and legacy crafted from alpine granite and guided by Swiss expertise, made for those who see time as something worth preserving.

The Making of the RockWatch

It all begins with granite sourced from the heart of the Alps. Granite extracted during the renovation of the Jungfrau Tunnel is delivered to the workshop in large blocks. Cylinders are then obtained through milling, which are further cut into smaller sections to reduce internal stress within the stone, making it easier to handle during the machining stages. To preserve the spirit of the original RockWatch, these raw pieces

are then entrusted to the very same artisans who crafted the first edition in 1985, ensuring that the process remains as authentic and faithful to its origins as possible.

These blocks are then shaped and refined, gradually approaching the final case diameter of 38mm. The granite undergoes a meticulous grinding process, where controlled pressure and abrasive compounds are used to achieve a smooth, uniform surface. Guided by tools operating with micron-level precision to sculpt the outer profile, making sure each piece meets strict dimensional standards.

At this stage, the stone is ready to be hollowed. This process is one of the most delicate in the entire production. Technicians carve out the central cavity with sub-millimeter finesse. This hollow space is essential for housing the movement, the accuracy required here is uncompromising: the integrity of the stone and the performance of the watch depend on it.

To secure the case back and keep the movement in place, a steel container is fixed inside the stone case. This structural element provides stability allowing the movement to be housed securely.

The font marking with the logo is then applied using pad printing, a technique that uses a soft silicone stamp to gently transfer the design onto the stone’s surface. A fine layer of acrylic paint is used, to ensure a crisp, lasting finish that complements the natural character of the stone.

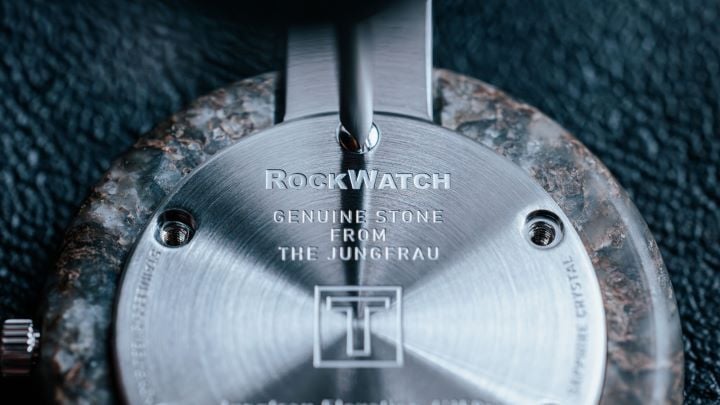

Once the movement is assembled inside the container, the hands and the sapphire crystal are added. Tissot’s hands, crafted from stamped brass, are polished, and subtly curved to follow the contours of the granite surface a detail that adds complexity and precision to the assembly. Above them, anti-reflective domed sapphire crystal, highly resistant by its material, shields the hands beneath. Its domed form mirrors the shape of the case, enclosing the watch face while allowing the intricate details of the granite to be admired without glare. After this, the final touches begin. The engraved case back featuring “Jungfrau - Top of Europe” and a unique serial number is carefully affixed and screwed into place and the bracelet is finally assembled.

The RockWatch stands as a reminder of the ingenuity it took to bring such a concept to life in 1985. Tissot was able to engineer a timepiece from stone at a time when such craftsmanship seemed unimaginable, which speaks volumes about the brand’s visionary spirit. Over the years, Tissot has mastered the techniques, refining them, and now, the new RockWatch is ready to conquer new territories. Released in a limited edition of 999 pieces, each watch comes in a special collector’s box designed to resemble a block of granite, echoing the raw beauty of the mountain the case came from.